our requirements

Our blast room is 14’ x 21’ and our oven is 10’ x 25’ so our projects must fit inside these parameters. If your project can be disassembled prior, it will drastically improve the turnaround rate. We hang your projects on small to large rolling racks, so please provide or indicate “hook hole(s)” capable of supporting the weight to help our process. Let us hook you up.

COLOR OPTIONS

There are thousands of color options available, including different gloss levels and textures. We have accounts with most powder manufacturers, so we can get the powder that you need. Some special effects powders, or metallics, require 2 or 3 stage coatings. We stock hundreds of colors and can provide color swatches or samples. Custom powder colors can usually be obtained within a few days. Look below for our coating providers’ information and if you’d like, choose your color(s) in advance!

PROCESS

Powder coating is a process of painting using dry powder paint resins applied onto metal parts using specialized electrostatic spray equipment. This creates a corona magnetic field. After application, the powder is cured in our oven until the part reaches 400 degrees for 10 minutes for most powders. Any bushings, plastic, rubber or bearings that cannot bake must be removed prior the process. Once the powder is cooled to ambient temperature the parts can be handled. No additional cure time is required. The powder coated finish is not only beautiful, but more durable and cost effective than liquid painting. Another advantage of powder coating is that it releases no VOC’s (volatile organic compounds), and thus is more environmentally friendly.

PREPARATION

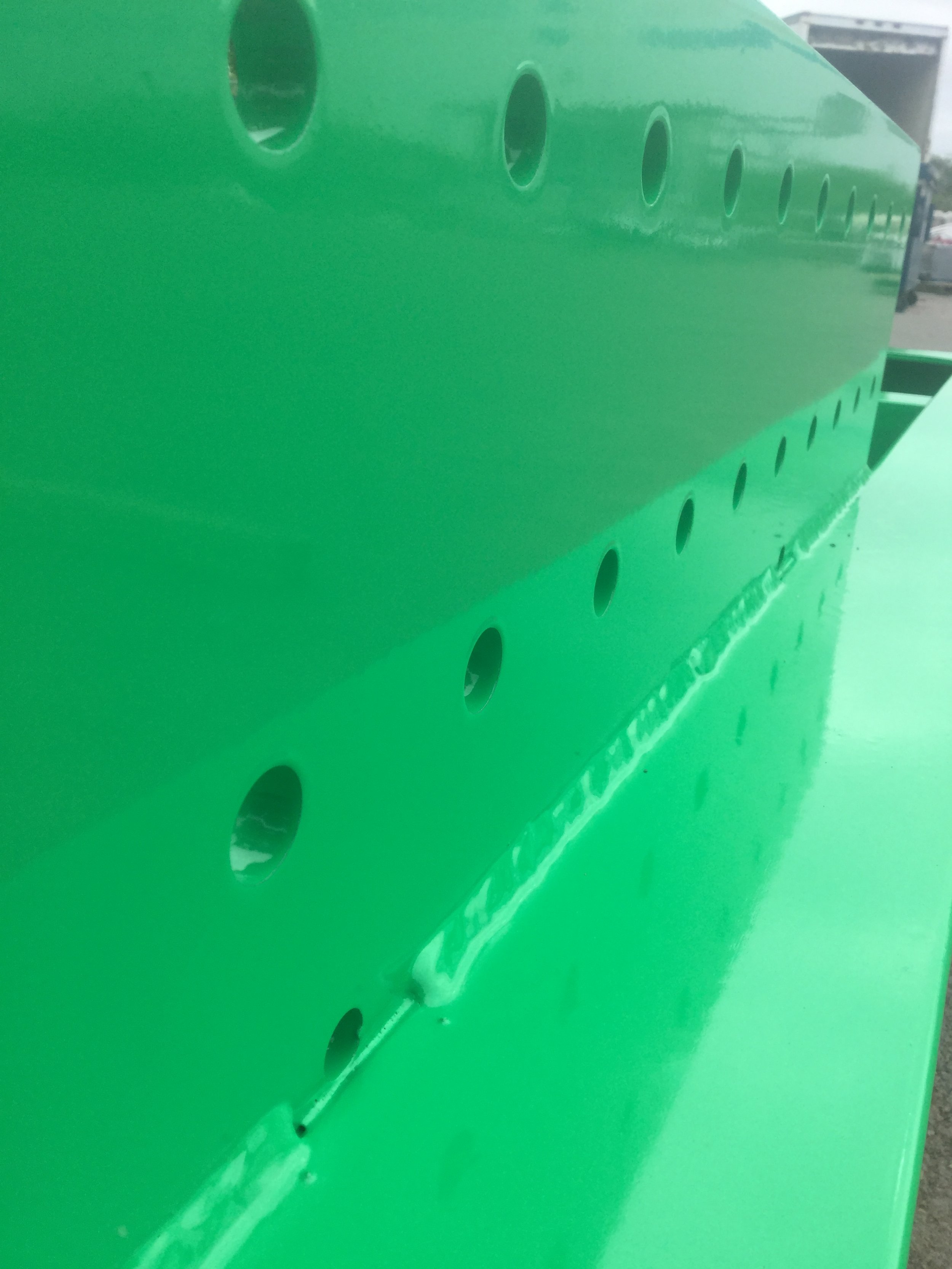

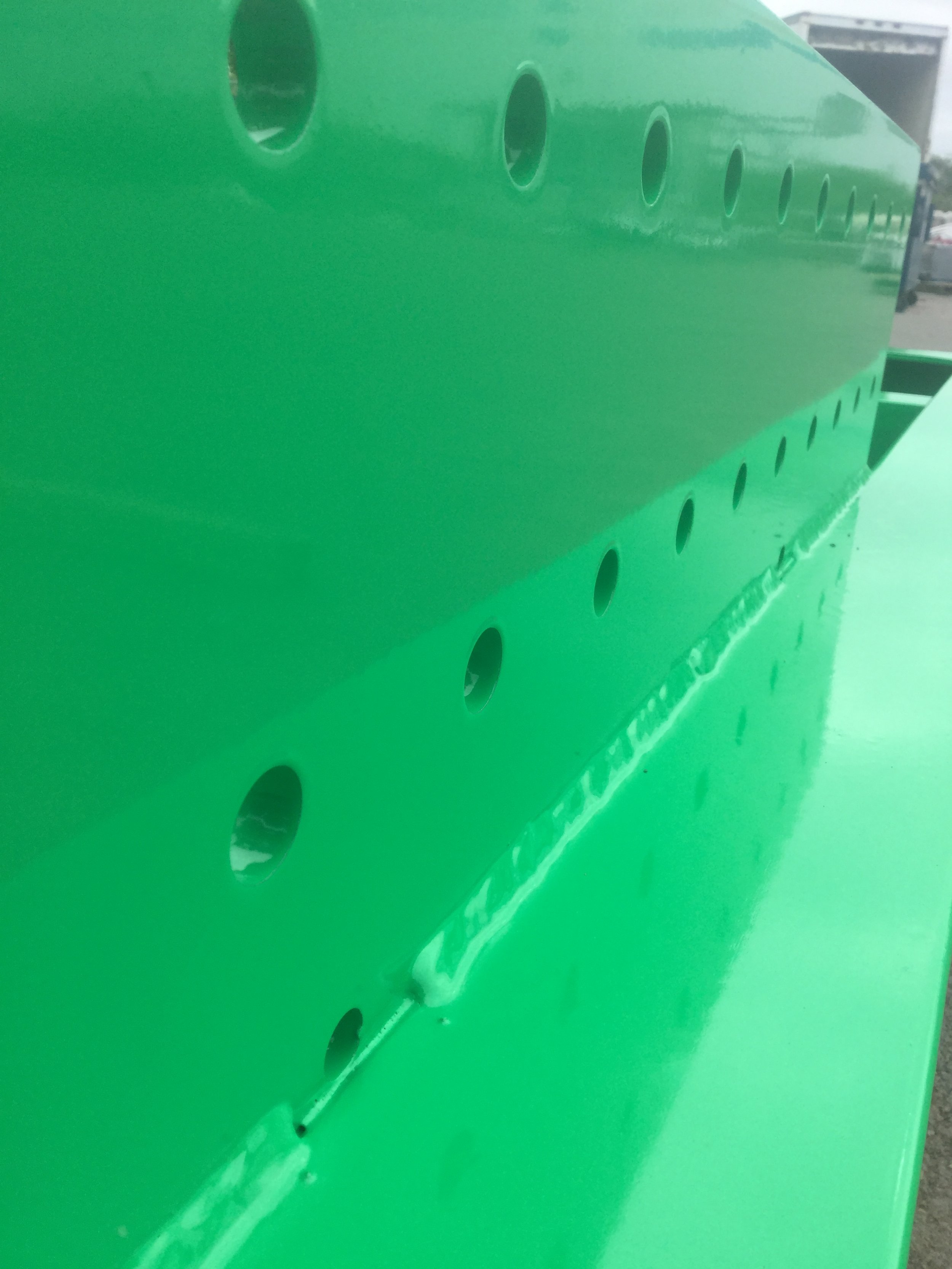

Proper substrate preparation is essential for a quality and lasting finish.

Removal of oils, dirt, mill scale, and proper metal etching/profiling are done either with sandblasting or chemical pretreatment. It is recommended that we sandblast all hot rolled steel to remove the mill scale. Most cold rolled steel, stainless steel, and aluminum can undergo chemical pretreatment. This process is also used to avoid sandblasting thin sheet metal parts that are prone to warping. Metal parts that prone to warping are due to excess amounts of heat and pressure. The molecular composition of the metallic substrate is versatile it it’s attributes. Please contact us about which substrate you would like to use. We use a heated degreaser for cleaning and then chemical conversion, “etching“, with Zirconium for Aluminum or Iron Phosphate for steel preparation.

MASKING

You may not want every part of your project coated, so we take care to mask any bolt/studs, threaded holes, or other areas that cannot receive paint. We have a variety of heat tolerant tape, plugs, and caps so that proper masking is ensured. Our staff has years of experience analyzing masking drawings and instructions.

COATING SUPPLIERS WE USE

We have numerous types of powder and sources therein! 60-70% of powder coating’s ingredients are recycled. Any overspray of our powder coating is collected, baked, and sent to a recycling plant. Here’s a brief list with links of those powder manufacturers:

IFS POWDERS® are an environmentally responsible choice. There are no-low solvents or VOCs in their powder coatings. IFS POWDERS® coatings can achieve heightened chemical, mechanical and weathering performance with a single coat. This means less product used AND less energy used in application and cure. Find the color you’re looking for here:

PRISMATIC POWDERS® “Prismatic Powders offers the world’s largest color selection of custom powder coatings. With over 7,000 and finishes, they are powder coating’s creative outlet!” For small custom projects, Prismatic Powders is a go-to because they offer small batches of powder! That way, you don’t have to spend extra on a larger quantity than you need. Search here for your color: https://www.prismaticpowders.com/shop/powder-coating-colors

CARDINAL PAINTS AND POWDERS®: “A leader in the manufacture of high quality coatings, we offer a wide range of liquid and powder coating systems. These were developed to meet and exceed the most demanding performance and emission standards. Cardinal’s reputation is based upon our dedication to solving customers coating challenges. From facilities across North America and Asia, we are ready to provide the solution to your coating challenges.” These are the colors in which Cardinal’s provides: http://www.cardinalpaint.com/powder/color-chart

PPG®: “PPG powder offers a myriad of benefits over other coatings, including low production cost per unit, specifically formulated without VOCs, easy to reclaim and recycle, extended durability, exceptional chip and abrasion resistance and 95% transfer efficiency. PPG has extensive experience in powder across the globe, allowing our team to provide additional value, service and intelligence to all our customers, regardless of location.” Please check out their hue selections: https://powdercoatings.ppg.com/collections/all

SHERWIN-WILLIAM’S POWDURA®: “The right color, when and where you need it. Our Powdura products are available in a wide assortment of colors, textures and glosses through our facility network. You can also choose from a range of technologies, including: epoxies, urethanes, hybrids, TGIC-free, primers, polyesters and specialty chemistries” https://industrial.sherwin-williams.com/na/us/en/general-industrial/color/powdura-color-cards.html

Call/Text (541) 237-8888